Contact:

Volkswagen Front Suspension

VW used double trailing arms mounted in twin front torsion spring housings in the front of their autos. Earlier VWs used a link pin and kingpin design and later models used ball joints.

www.thesamba.com Front Suspension

The front torsion arm suspension is equipped with two trailing arm on either side of the front beam. This allows for a good travel arc that arcs the front wheel up and back (not towards) away from obstacles, reducing upward strain/shock on the suspension and vehicle particularly at high speeds. This durable design makes it work very well for off-roading because of its travel shape being an arc.

The basic principle of the Beam - Torsion arm suspension is to have two parallel tubes running a few inches apart. There are four arms, two on either side of the beam which pivot at two ends: one side pivots within the beam which is bolted to the car, and the other side pivots at the spindle around a Linkpin or a Balljoint.

Type 1 Beetles produced in 1965 and earlier came from the factory with a Linkpin pivot torsion arm front suspension. This setup allows for full cycling of the suspension without the binding limits inherent in ball joints. This makes the Linkpin setup more ideal for offroad use since you are able to benefit from potentially much greater suspension travel. This same lack of binding also makes linkpin setups more desirable for those that choose to lower their VWs as far as they can go. The front beam has two torsion tube which are 4 3/4 inches center to center.

Type 1 Beetles produced between 1966 and 1977, the end of German production of the standard Beetle, were equipped with a Ball-joint pivot torsion arm suspension. The overall design of the balljoint front end is very similar to the earlier linkpin/kingpin design. The main difference is that the torsion tubes are further apart from each other and the out end of the torsion bars incorporate more modern ball joints. These ball-joint have misalignment limits and are the limiting factor in up and down travel of the front suspension. At their maximum limits, they will bind and potentially become damaged. The torsion tube separation on Ball-Joint beams is approximately 5 3/4 inches center to center.

Super Beetles incorporated a MacPherson-strut system that is not designed for any off road use. The Mexican-built Beetles' front-end has additional re-enforcement plates not found on the hammer-head chassis from Germany and are more durable than the European Supers.

Complete Front Beams:

Lengthened/Widened Beam

Used to widen your track for increased stability especially when turning. The most common is going 6" wider than stock. Wide beams can be purchased in a variety of configurations from 10" travel shock towers for coil-overs or no shock towers at all for use with torsion leaves.

thesamba.com Building a Widened BJ Beam

Narrowed Beams

This is commonly done on street rods to allow wider tires to fit under the front fenders. This decreases overall stability of the VW.

Type 3 Beam

The Type 3 beam is wider than a Type 1, has 2-1/2" longer arms, uses torsion bars instead of leaf springs and has disc brakes. This is not a bolt on modification and will require a good amount of fabrication to mount the beam further out to allow your tires to still fit in the wheel wells. The ball joints can be removed in the field without the need for a press.

Thing Beam

The most common suspension upgrade for the Ball-Joint front end Type 1 Beetles is to incorporate components from a VW Thing (Type 181) front end. This has extra reinforcement on the shock tower and attachment points for Thing beam supports. Thing spindles and trailing arms will provide some lift and can be used on the type 1 ball joint beams.

What makes the Thing spindles stronger aside from any casting differences is that the Ball-joints are pressed in from above (instead of one from above and one from below like the stock Beetle), this prevents knocking a Ball-joint loose on a hard impact. Thing components are a direct swap and will provide approximately 2.5" of front lift.

Ball Joint to King Pin

If you have a Baja or buggy project with a 1969 or later Beetle equipped with Independent Rear Suspension (IRS), you may want to upgrade your car to the earlier Linkpin suspension and abandon the Ball-joint beam originally holding up the front of your vehicle. This will allow for greater front suspension travel durability, two desirable features in an off road vehicle. This unfortunately is not a straight forward swap as the separation between the two torsion tubes of the linkpin and ball-joint beams differ by about an inch. There are however several ways to go about converting a newer VW to use an earlier setup.

Adapter

You can use an adapter to bolt a complete linkpin front end to a previously ball jointed body. This is probably the easiest way of going about this conversion but has some drawbacks. For one, the adapter will push the front beam forward a bit. This may be desirable if you would like to use longer torsion arms, but also places greater stress on the mounting point of the front beam to the framehead.

Adapter

Old adapters may be difficult to find, but luckily, newer ones are also available.

http://www.thesamba.com/vw/classifieds/detail.php?id=787535

Grind and Fit Method

Many budget VWer seem to be fine with reshaping the ball-joint framehead with a grinder to fit a linkpin beam. This doesn't seem like a good idea al all, but again seems to be common practice by many a backyard mechanic. And with a little bit of reinforcement and quality welding, this should work fine for most applications.

Ball Joint Framehead cut to fit Linkpin Beam (Rack and Pinion also added)

http://www.thesamba.com/vw/forum/viewtopic.php?t=314267

Framehead Replacement

With just the right amount of welding experience, you can weld on a linkpin framehead to a ball-joint body. You can get a link pin framehead from a donor VW or many aftermarket VW shops. And done right, this allows for a stock strength clean conversion.

http://www.thesamba.com/vw/forum/viewtopic.php?t=63491

http://fvwa.sitefactory.fi/data/10.pdf

http://www.mamotorworks.com/acvw?frame=1.4627

http://www.volksrods.com/forum/showthread.php?t=27457

Cage Fabrication

If you have or are fabricating a cage for the front of your VW, you can set it up to fit what ever front beam you like and wherever you like it. A front cage also has fabrication potential for overall strength, shock towers, lights, body mounts, etc.

Hybrid Beam

There are a few ways to create a hybrid linkpin/ball-joint beam that "bolts on" to a VW.

A "combo-beam" is mentioned in the forums. This is a linkpin outer beam with a ball-joint inner beam welded together. This allows the center section to bolt to a new framehead, while having a linkpin suspension. This may also increase the overall width of the front end if the linkpin beam sections aren't trimmed.

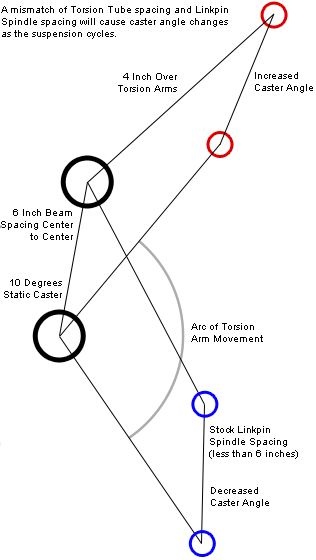

Another method is to build a linkpin beam with same torsion tube separation as a ball-joint framehead. The guy at Bugzyla makes these and swears by them. They look nice and should bolt right on. The problem is that if you use an unmodified linkpin spindle with this setup, the torsion arms will not be parallel to each other. This will cause significant caster changes as the front suspension cycles.

Bugzyla and others state the this hybrid system works well without noticeable steering problems, but the geometry does not seem right by any means. Their argument for use of conversion arms (see below) is this:

We have conversion arms available now for anyone interested. We have been testing these and the conversion beams for quite a while now. The linkpin beam tubes are actually about 4 3/4" apart cernter to center, while the link pins are actually about 5 3/16" apart center to center at the spindle carrier. The balljoint beam is 5 3/4 center to center on the tubes. So the stock linkpin beam is about 1/2" narrower than the linkpins center to center, and the balljoint beam is about 1/2" wider center to center. So while you are changing the geometry, its no more caster change throughout the travel between the 2, just in the oposite direction. These arms and conversion beams all but eliminate the bump steer issue, and they work great. I have a couple dozen of these beams in various cars from street cars, to weekend warriors, to all out race cars. The arms do the same thing as the beam if you dont want to swap beams. Stop by my shop anytime and have a look.

http://www.thesamba.com/vw/classifieds/detail.php?id=939587

http://www.azbaja.com/ForumsPro/viewtopic/t=5139/

http://www.thesamba.com/vw/forum/viewtopic.php?t=345781

Conversion Arms

Yet another hybrid option is to use conversion torsion arms. The fit on ball joint beams and allow for use of kingpin spindles and should have the same drawback or advantages of the hybrid beam concept.

http://www.azbaja.com/ForumsPro/viewtopic/t=7007.html

Ball Joint Removal

Removing the ball joints from the trailing arms on a ball joint front end can be a real challenge. It is generally thought that you need a press and the proper fittings to remove and install new joints. There are however other options. One is to use heat on your arms and a big hammer. This technique is questionable as it may change the temper on your arms.

http://www.harborfreight.com/3-in-1-ball-joint-u-joint-c-frame-press-service-kit-38335.html

http://www.busdepot.com/catalog.jsp?model=3&category=19 Meyle/Germany parts

Another options to replacing ball joints is to just to purchase rebuilt trailing arms with the ball joints already installed.

http://www.aircooled.net/new-bin/viewproductdetail.php?keyword2=SSB0008

High-Angle Ball-Joints

Another solution to Ball-joint suspension issues is high-angle Ball-Joints. These are not used much do to poor quality issues.

Front End Lift

The cheapest way to gain lift with your torsion arm suspension is to pre-load the torsion leaves. You can do this with the "cut and turn" method or by welding in adjusters.

Available through some VW parts shops are Lift Spindles. These lower the mounting point of the wheel in effect raising the front of the car and retaining completely stock suspension geometry for reliability and longevity.

http://www.tweedsdesigns.com/img/pages/spindles/spindles_AS-BJ.html Tweeds Designs - late model lift spindle

Trailing Arms

Another common upgrade is the use of longer/wider trailing arms. These will provide you with more suspension travel for a more comfortable/faster ride off-road. Obviously, the longer the trailing arm is, the more travel you will attain. This can range from about 9" with a maxed out stock setup to about 15" with 4" longer arms and coilover shocks. Stock arms can be modified with a long travel shock mount for better control of the shock throughout the suspension range.

Beefing UP

A flaw with the stock beams is that they were designed for the autobahn and not for real off-road abuse. They are mainly tack-welded together and you can increase the strength of the front end by welding the seams with a MIG and gusset where the shock towers meet the upper beam tube.

For Link/Kingpin suspension, you can gussets on the weak points of stock spindles (around the king pin carrier and tie rod arm) and the beam. Another spindle upgrade is combo spindles - much stronger and much more expensive.

For Ball Joint Suspensions, you can also beef up the spindles.

http://www.thesamba.com/vw/forum/viewtopic.php?t=365665&start=33

Limiting Suspension Travel

You can and perhaps should use limiting straps to limit downward travel. This prevents your shocks from bottoming out, your ball joints from breaking (if you have a ball joint front end) or other suspension damage.

http://www.thesamba.com/vw/forum/viewtopic.php?t=365665&start=62 - welded on bolt for limiting strap

Another novel way to limit travel is to build in hard stops.

http://www.thesamba.com/vw/forum/viewtopic.php?t=365665&start=60

A Arms

This design allows for suspension control that can allow for good steering and camber control and the potential for long travel, all depending on design.

5 and 4 Lugs

Most-off road VWs use the early 5-lug wheel because of it's superior strength compared to the 4-lug wheel and because the link/king pin front ends come with 5 lug setups.

If you are running a Ball Joint front end you can use 5-lug 66-67 front drums if you use the 68 and later inner wheel bearing. If you have a King & Link front end then you are pretty much stuck with a 5-lug drums up front unless you upgrade to an aftermarket conversion.

Torsion Beam Bearings

VWs cam with metal roller bearings in ends of the beams. Aftermarket replacement bearings are still available, but the original German ones seem to be hard to find. Many VWers also use polyurethane or derlin as bearing replacements front and rear. The quality of the available polyurethane bushing seem to be in question and the derlin bushings seem to be a bit firmer and more durable. Some have even reported that their polyurethane bushing have failed within a year or even as early after a single offroading run. Both the poly and derlin bushings may need to be reamed out for a proper fit.

http://www.thesamba.com/vw/forum/viewtopic.php?t=402712

http://www.sacoperformance.com/products.php?cat=28

http://www.thesamba.com/vw/forum/viewtopic.php?t=211720

http://www.pacificcustoms.com/AC413115.html

Some VWers have gone as far as modifying their beams to fit other bearings to allow for easy to find quality replacement parts.

http://www.thesamba.com/vw/forum/viewtopic.php?t=402712&start=10

"Local bearing shop, we shrank a steel insert over the arms, and fitted a pair of gold speedi-sleeves to give a bearing surface, and pressed in a stainless sleeve in the beam to bring it down to the closest off-the-shelf size.

It's a bit of work, but they've held up damned well, we've had to replace every other bush on the car after this season but they're fine."

Inner Micarta/phenolic Bushing

http://www.thesamba.com/vw/forum/viewtopic.php?t=355617

http://www.thesamba.com/vw/forum/viewtopic.php?t=323551

King Pin Stock Bearings

Inner 111 405 627 Outer 111 405 647 Seal 111 405 641A

Ball Joint Stock Bearings

Outer Upper 46mm Upper Torsion Arm Needle Bearing

111 40 1301 Outer Lower 50mm Lower Torsion Arm Needle Bearing

311 40 1301C Upper Torsion Arm Seal

131 40 5131 Lower Torsion Arm Seal 131 40 5129 Upper Ball Joint 131 40 5361F Lower Ball Joint 131 40 5371G Ball Joint Replacement Boot Kit with Clips 131 49 8001

Please feel free to link to this site so that others can find it. It's easy to link to this site, just copy one of the texts below onto your web page:

Copyright © 2000-2010