Contact:

Volkswagen Weber Progressive Carburetor

The Weber Progressive carbs can work great for a VW or be an utter nightmare, depending on how it is set up. And unlike other double barreled carburetors, this one isn't designed with two synchronous barrels meant to feed separate halves of a V8 engine. This double barrel system instead has a primary barrel used solely at low to half throttle operation and a second barrel that opens up when you increase your throttle allowing for increased air and fuel delivery at wide open throttle. This allows of better low throttle economy with the option for increase performance on demand. It can also make tuning more of a challenge than with single barrel and regular double barrel carburetors.

On VWs, these are generally used as center mount systems but there were kits sold in the past that allowed you to mount duals.

Manifold Heat - Stop VW Carb Icing

For fuel to be delivered to the combustion chambers ready to burn the fuel must be vaporized. If your air fuel mixture isn't warm enough, you will need to run a much richer mixture to compensate for the fuel that condenses on its journey through the intake manifolds. The pooling of this condensed fuel in the manifolds not only makes it challenging to tune your idle, but will sucked into the combustion chambers all at once when you open up the throttle creating a too rich burn condition.

In dual carburetor setups, the metered fuel only need to travel a very short distance straight down into the combustion chamber. There isn't much time to cool down and the short length of the intake manifolds also don't take long to heat up from direct contact with the heads. But dual Progressive setups are rare these days and kits are not longer made.

On the other hand, in a center mount progressive carburetor system, your metered air/fuel mixture must travel downwards a good distance and then make a 90 degree turn, travel some more and them make another 90 degree turn into the combustion chamber. Only the very ends are in direct contact with the heated heads and the rest of the manifold can easily cool down due to all of its surface area exposed to air. This setup makes it all too easy for fuel to condense on its way to the heads and a center mount progressive system must be heated for it to properly function. Because of this, they won't work in a Type 4 VW.

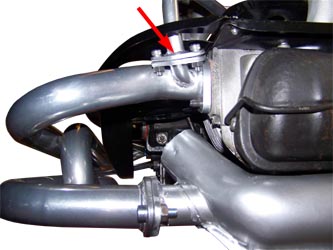

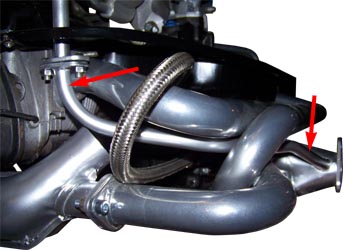

The best working systems use heat from the exhaust. The stock VW exhaust for Type 1 has one exhaust port that connects to the header's base where it connects to the #2 cylinder side of the right head (mirror image in Mexi Beetles) and one exhaust port that snakes its way into the muffler. This allows a high pressure side and a low pressure side which in turn pushes hot exhaust gasses through the heat riser tubes into the manifold and out into the muffler. Unfortunately, many aftermarket headers just have exhaust ports at the base of the #2 and #4 cylinders. This gives a nice symmetrical look but basically only allows gasses to pulse back forth through the two sides of the heat riser tubes. This pulsing doesn't allow for an efficient transfer of heat and can lead to premature carbon build up in the tubing and manifold.

If you are using an aftermarket or custom exhaust, you will want to have one exhaust port at the base of one of your exhaust pipes and another exhaust tube that joins at the collector. This will allow heat to travel from the base of one pipe, through one heat riser, into the intake manifold, out the other heat riser and into the collector.

|

|

| High pressure exhaust port at base of #2 cylinder | Low pressure exhaust port adjacent to #4 cylinder and into collector |

Another heat option is to run warm engine oil through the manifold and back to the engine. You will need to have a quality and cleaned out manifold and not one that is porous.

Heated Manifolds

There are several options for heated manifold and quality and functionality varies greatly! Ideally, you will want a manifold that runs heat through the bottom of the manifold, up to the base of where the carb sits and back down through the bottom so that the entire manifold is heated. Red Line has a nice system that also has the proper linkage to allow for full open throttle on a VW without any accelerator modifications.

Most other heated manifolds just run heat through the bottom of the manifold itself. These are generally not sufficient for reliable lower temperature (below 40 deg F) use.

Ref:

Cleaning a Carbon Clogged Heat Riser Tube

Why do I need to heat a center 2 bbl carb setup?

Not another Class 11 (style)... Pictures of exhaust setup

Heated Air

Routing heated air to your carburetor helps. You can simply use rain gutter downspouts to redirect heated air from under your heads to the air intake or get fancy with a heat collector around your exhaust.

Ref:

Linkage

If your kit didn't come with special VW specific linkage, than you won't be able to use the progressive circuit unless you get this linkage, drill out a hole higher on your accelerator for the throttle cable, or get creative.

Carburetor Choices

Weber has a FDEV and a FDAV. The FDEV has an electric choke and the FDAV has a water choke. The FDEV is preferred for an air cooled VW since there isn't heated water to operate the FDAV.

There are also EMPI progressive knock offs. The quality of EMPI carbs can be quite poor and these should be avoided.

Fuel Pressure

Weber carbs need 3-3.5 PSI of fuel pressure and properly set floats.

Jetting

Jetting can be problematic as different shops and drivers run a wide gamut of configurations. For a progressive carburetor, only one barrel is open during the normal operating range. When the second barrel opens up, the available amount of air running through each barrel drops, causing an overall decrease in carb vacuum. To compensate for the decrease in air flow and vacuum through each barrel, the secondary jets need to be larger than the primary to compensate and prevent a lean state when the the progressive circuit opens. And if you don't do this, John Connolly from aircooled.net will slap you upside your head. Here are his recommendations:

Idle Jets

Primary Idle :

45-50 at sea level

40-45 at 5000 feet

The hotter your manifold, the smaller your idle jet

Secondary Idle :

10-15 Larger (opposite from Weber setup) than primary idle

Main Jets

Primary Main:

125

Secondary Main:

180-190

Air Jets

160-180

160 on primary

180 on secondary

Aircooled.net Jetting Recommendations

| Elevation | Pri Idle | Sec Idle | Pri Main | Sec Main | Pri Air | Sec Air |

| Sea Level | 45 | 60 | 125 | 190 | 160 | 180 |

| 4,000 Ft | 45 | 55 | 120 | 180 | 175 | 190 |

| 8,000 Ft | 40 | 55 | 115 | 175 | 190 | 205 |

If you aren't running a quality heated manifold, then you will need to compensate with a richer mixture and adjust your jets appropriately.

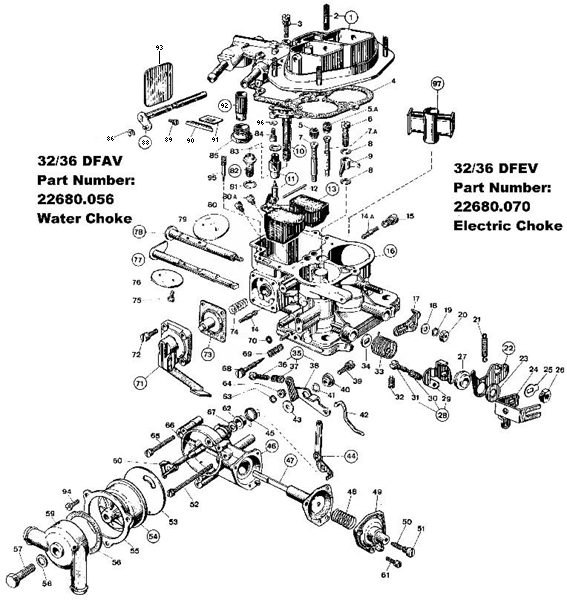

Carburetor Breakdown

32/36 DFEV – PART NO. 22680.070

| No | Qty | Description | Part Number | No | Qty | Description | Part Number | |

| 1 | 1 | Carburetor Cover Assy | Not Serviced | 51 | 1 | Screw Plug | 61015.003 | |

| 2 | 4 | Stud Bolt | 64955.002 | 52 | 1 | Screw Securing Auto Choke Body | 64700.015 | |

| 3 | 5 | Top Cover Fixing Screw | 64700.005 | 53 | 1 | Gasket For Auto Choke Body | 41640.005 | |

| 4 | 1 | Top Cover Gasket | 41705.034 | 54 | 1 | Auto Choke Thermostat Assy | 57804.076 | |

| 5 | 1 | Primary Air Corrector Jet | 77201.* | 54a | 1 | Electric Choke Thermostat | 57804.332 | |

| 5a | 1 | Secondary Ari Corrector Jet | 77201.* | 55 | 3 | Thermostat Assy Locking Ring | 52135.006 | |

| 6 | 1 | Pump Delivery Valve Assy | 64290.024 | 56 | 1 | Water Chamber Seal Gasket | 41555.001 | |

| 7 | 1 | Primary Emulsion Tube | 61440.* | 57 | 1 | Water Cover Fixing Screw | 64615.001 | |

| 7a | 1 | Secondary Emulsion Tube | 61440.* | 58 | 1 | Gasket For Screw | 41530.002 | |

| 8 | 2 | Pump Jet Gasket | 41540.014 | 59 | 1 | Auto Choke Water Chamber | 32444.010 | |

| 9 | 1 | Accelerator Pump Jet | 76211.* | 60 | 1 | Choke Shaft & Lever Assy | 10085.031 | |

| 10 | 1 | Power Valve Assy | 57804.025 | 61 | 3 | Screw Securing Auto Choke Cover | 64700.007 | |

| 11 | 1 | Needle & Seat | 79519.* | 62 | 1 | Spring Retaining Cover | 58000.018 | |

| 12 | 1 | Float Fixing Pin | 52000.015 | 63 | 1 | Spring Washer | Not Serviced | |

| 13 | 1 | Plastic Float | 41030.022 | 64 | 1 | Fixing Nut | Not Serviced | |

| 14 | 1 | Primary Idle Jet | 74403.* | 65 | 2 | Screw Securing Auto Choke Body | 64700.023 | |

| 14a | 1 | Secondary Idle Jet | 74403.* | 66 | 1 | Plate For Choke Shaft | 52130.012 | |

| 15 | 2 | Idle Jet Holder | 52570.005 | 67 | 1 | Washer For Shaft | 55555.029 | |

| 16 | 1 | Carb Body | Not Available | 68 | 1 | Idle Adjusting Screw | 64750.001 | |

| 17 | 1 | Secondary Throttle Control Lever | 45032.013 | 69 | 1 | Spring For Idle Adjusting Screw | 47600.007 | |

| 18 | 1 | Flat Washer | 55510.046 | 70 | 1 | Gasket For Auto Choke Body | 41565.008 | |

| 19 | 1 | Spring Washer | 55525.001 | 71 | 1 | Accelerator Pump Cover Assy | 32486.034 | |

| 20 | 1 | Fixing Nut | 34705.001 | 72 | 4 | Pump Cover Fixing Screw | 64700.004 | |

| 21 | 1 | Spring For Loose Lever | 47605.010 | 73 | 1 | Accelerator Pump Diaphragm Assy | 47407.261 | |

| 22 | 1 | Primary Loose Lever Assy | 45069.006 | 74 | 1 | Pump Loading Spring | 47600.107 | |

| 23 | 1 | Flat Washer | 55510.061 | 75 | 4 | Throttle Valve Fixing Screw | 64520.023 | |

| 24 | 1 | Throttle Control Lever | Not Serviced | 76 | 1 | Primary Throttle Valve | 64005.090 | |

| 25 | 1 | Lock Washer | 55520.002 | 77 | 1 | Primary Main Shaft Assy | Not Serviced | |

| 26 | 1 | Fixing Nut | 34715.014 | 77a | 1 | Primary Main Shaft Assy Oversize | 10016.475 | |

| 27 | 1 | Bushing For Loose Lever | 12765.002 | 78 | 1 | Secondary Main Shaft Assy | 10015.413 | |

| 28 | 1 | Lever For Throttle Adjusting Screw

Including: |

Not Serviced | 79 | 1 | Secondary Throttle Valve | 64005.034 | |

| 29 | 1 | -Lever | 45039.022 | 80 | 1 | Primary Main Jet | 73801.* | |

| 30 | 1 | -Spring | 47600.073 | 80a | 1 | Secondary Main Jet | 73801.* | |

| 31 | 1 | -Screw | 64625.006 | 81 | 1 | Power Valve Gasket | 41530.013 | |

| 32 | 1 | Secondary Throttle Adjusting Screw | 64595.005 | 82 | 1 | Full Power Need Valve | 64235.016 | |

| 33 | 1 | Primary Shaft Return Spring | 47610.012 | 83 | 1 | Gasket For Needle Valve | 83102.070 | |

| 34 | 1 | Washer | 55555.016 | 84 | 3 | Power Valve Fixing Screw | 64700.007 | |

| 35 | 1 | Fast Idling Loose Lever

Including: |

Not Serviced | 85 | 1 | Strainer Inspection Plug | 61002.018 | |

| 36 | 1 | -Screw | 64590.004 | 86 | 1 | Locking Ring | 10140.501 | |

| 37 | 1 | -Spring | 47600.007 | 88 | 1 | Choke Shaft & Lever Assy | 10020.214 | |

| 38 | 1 | -Lever | Not Serviced | 89 | 4 | Choke Plates Fixing Screw | 64525.003 | |

| 39 | 1 | Screw Securing Fast Idle Loose Lever | 64700.014 | 90 | 1 | Dust Seal Plug | 61070.002 | |

| 40 | 1 | Bushing For Fast Idle Loose Lever | 12765.042 | 91 | 1 | Dust Seal Plate | 52135.018 | |

| 41 | 1 | Washer | 55530.005 | 92 | 1 | Strainer Assy | 37022.010 | |

| 42 | 1 | Fast Idling Control Rod | 61280.042 | 93 | 2 | Choke Throttle Valve | 64010.006 | |

| 43 | 1 | Flat Washer | 55510.003 | 94 | 3 | Screw For Thermostat Plate | 64615.005 | |

| 44 | 1 | Choke Shaft Control Lever | Not Serviced | 95 | 1 | Pump Discharge Blanking Needle | 64900.001 | |

| 45 | 1 | Spring For Fast Idle Cam | 47610.083 | 96 | 3 | Flat Washer | 55510.038 | |

| 46 | 3 | Auto Choke Body Assy | 57804.072 | 97 | 2 | Auxiliary Venturi | 71110.* | |

| 47 | 1 | Choke Diaphragm Assy | 47407.080 | 98 | 1 | Choke Device 35-52; 61-67 | 57804.119 | |

| 48 | 1 | Spring For Diaphragm | 47600.141 | *Calibrated Parts Require 3 Digits To | ||||

| 49 | 1 | Cover For Choke Diaphragm | 32384.022 | Complete Part Number | ||||

| 50 | 1 | Diaphragm Adjusting Screw | 64595.005 | See Calibrated Parts Section For Sizes. |

Please feel free to link to this site so that others can find it. It's easy to link to this site, just copy one of the texts below onto your web page:

Copyright © 2000-2010