Contact:

Volkswagen Spark Plugs

Spark Plug

NGK and Bosch spark plugs are the most popular plugs used by VWers. The older Bosch ones are no longer being made and can be hard to come by. The newer platinum Bosch spark plugs don't seem to work as well as the original Bosch plugs, but luckily we still have plug options.

Rolled Threads

Bosch uses rolled threads. Rolled Thread is the process in which the threads are cast as part of the original steel shell vs. a cut thread which is machined after the shell is cast. Which process is better depends on application. For spark plugs, rolled threads are better as the threads are cast and hardened along with the steel shell, also the grain structure obtained in the hardening process is not interrupted, having a higher structural integrity. The nickel plated rolled Bosch threads are often smoother than other spark plugs and believed to have a lower likelihood of seizing.

NGK plugs have cold rolled threads to prevent damage to aluminum heads.

Diehard VWers generally use Bosch or NGK plugs over cut thread plugs to decrease the occurrence of the plugs damaging the VW heads. If you strip a plug hole, you can use a TIME-SERT self locking insert to repair it. Helicoils can unfortunately unwind themselves.

Stock Plugs

Stock VWs used Bosch spark plugs that have been discontinued. There are newer replacement spark plugs available and the following information should make it easier for your to find what will work.

Type 1 OEM

W 145T1 (Temperate) (Normal)

W 175T1 (Tropical) (High Speed)

Spark Plug Cross Reference Charts

Short Reach Plugs - T-1, 2, & 3 applications

14 x 1.25mm thread

1/2" (12.7mm) reach

13/16" (20.6-20.8mm) hex size

Long Reach Plugs - T-4, 914 Porsche, & Rabbit

14 x 1.25mm thread

3/4" (19mm) reach

13/16" (20.6-20.8mm) hex size

14mm 1/2" (12.7mm) Reach

| Tip | Bosch | NGK |

| Standard | W8AC | B5HS |

| Standard | W7AC | B6HS |

| Racing | W8BC | BP5HS |

14mm 3/4" (19mm) Reach

| Tip | Bosch | NGK |

| Standard | W8CC | B5ES |

| Racing | W8DC | BP5ES |

Cross reference Bosch W5A - Y6DC to NGK

Bosch

|

These resistor-less plugs are still out there in VW garages and a few stock rooms.

14mm Short Reach - T-1, 2 & 3 W8Ac (7502 & W 145T1) - superseded by WR8AC+ W7Ac (7596 & W 175T1) - superseded by WR7AC+

14mm Long Reach W8Cc (7504 & W 145T2) - superseded by WR8Cc+ W7Cc (7598 & W 175T2) - superseded by WR7Cc+

W8's are hotter running plugs for most normal driving conditions as well as colder climate and lots of stop and go traffic.

W7's are colder running plugs for warmer climates and extended/high rpm highway driving. These were the plug of choice when building those hi-performance motors as well because these motors tend to run a little hotter than stock. |

|

These resistor plugs replace the old Bosch standards. Note the R in the plug model. The only purpose of the resistor is for radio noise suppression which should be done with the ignition wires. A certain amount if resistance is necessary to dissipate reflections that travel up and down the ignition wire and radiate noise.

Standard Tip - 14mm Short Reach Resistor; Nickel Alloy Tip; Copper Core WR8Ac (7902) - Fits All T-1, 2, & 3 Applications Requiring Standard Heat Range. WR7Ac (7996) - Recommended For T-1, 2 & 3 W/High Compression, Sustained High Speeds, Unleaded Fuel, And Fuel Injection.

Standard Tip - 14mm Long Reach WR8Cc (7904) - Standard Heat Range Plug For All Stock 1700, 1800, 2000 Engines. Type 2 72-79, Vanagon 80-83, Type 4 71-74, 914 Porsche WR7Cc (7998) - Recommended For T-4 & 914 Porsche Engines With Higher Compression, Sustained High Speeds, Dual Carbs, Unleaded Fuel, And Fuel Injection.

|

|

Non-resistor; Platinum Tip; Platinum Core 14mm Short Reach W8Ap (4014) - Some VW parts retailers say that these are good for Extended Rpm, Dual Carbs, and High Compression use. W8AP (4214)

14mm Long Reach WR7Dp (4016) - Platinum Plug for 914 Porsche, T-4, and Rabbit engines being used in high performance environments and driving.

|

NGK

Note that the heat rating system used by NGKs is inverse that of Bosch.

|

14mm 1/2" Short Reach Resistor; Nickel Alloy Tip; Copper Core B5HS (4210) (comparable to Bosch W8AC) Standard Tip - Fits all T-1, 2, & 3 applications requiring standard heat range. B6HS (7534) (comparable to Bosch W7AC) Standard Tip - Recommended for T-1, 2 & 3 w/high compression, sustained high speeds, unleaded fuel, and fuel injection. Supposedly a great plug for dual carbs. BP5HS (4111) (comparable to Bosch W8BC) Racing Tip

14mm 3/4" Long Reach Resistor; Nickel Alloy Tip; Copper Core B5ES (6410) (comparable to Bosch W8CC) Standard Tip - Standard heat range plug for all stock T-4, 914 Porsche, & Rabbit. BP5ES (7832 & 2140) (comparable to Bosch W8DC) Racing Tip

|

|

14mm 1/2" Short Reach Resistor; Iridium Tip; Copper Core; BR6HIX (3419) - NGK's Iridium option

|

http://www.sparkplugs.com/sparkplug411_manufacturer.asp?manufacturerID=1

http://www.sparkplugs.com/sparkplug411_manufacturer.asp?manufacturerID=21

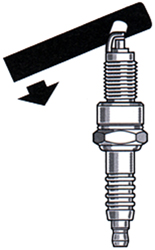

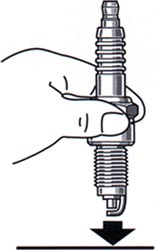

Installing Plugs

It is important to note that VWs use soft aluminum heads, which may be very very old. Care should be taken to avoid damaging the threads on your cylinder heads.

Before installing plugs, remove the small threaded terminal cap on the terminal as these are not compatible with VW plug wires. Lubricate the plug threads with a small amount of Anti-Seize compound. And ensure that the engine is cool before replacing spark plugs since the aluminum heads and steel plug threads expand and contract differently when heated, and you want to do everything you can to avoid damaging the threads on your heads. Torque plugs to 18 foot pounds of torque with anit-seize compound (lower than the 22 ft-lb recommendations).

Spark Plug Gapping

| Source | Gap |

| 72-'73 vehicle manual | 0.028" |

| Haynes | 0.028" |

| Official VW Service Manual '70 to '74 engines | 0.024" |

Running between 0.024" and 0.028" gaps seems to be the consensus in the aircooled world. If you are running a CDI, you can increase the gap to 0.040". Some VWers with CDIs run gaps up to 0.050".

To increase the plug gap, you should use a tool that only pulls back on the ground electrode without touching the center electrode or the porcelain. This is especially true for iridium spark plugs. This is because ultra-fine iridium can easily snap if mishandled. Because of this, some plug manufacturers feel that their plugs shouldn't be regapped. Their justification is that an iridium spark plug will run so much better than a traditional plug, even when it is not perfectly gapped for a specific application.

That said, you should use the proper tools and gap iridium plugs appropriately if you plan to run these. The exception to this includes the Bosch Ir Fusion plugs which have non-adjustable gaps according to the manufacture.

To close the gap on a plug, gently tap the plug, electrode first on a hard surface.

Resistor Spark Plugs

When the spark jumps across each plug gap, it causes a high frequency burst of energy known as RFI (radio frequency interference). This "noise" causes static on your radio and interferes with other sensitive electronic equipment. To combat this problem, resistor spark plugs were introduces in the mid 1960's. This plug technology places a resistor within the spark plug and suppresses RFI from the plug. Some later model vehicles as well as newer Powersport engines must use resistor plugs for a proper "talkback" to the electronic ignition.

Capacitive Discharge Ignition systems (CDI) used on outboard engines such as some Johnson and Evinrude marine engines and on some late model motorcycle engines are basically a refined version of the old magneto ignition system, except the points have been replaced with electronic circuitry. These ignitions systems produces less voltage than automobile ignition systems and use of non-inductive type plugs can cause misfires and poor performance. They require a special inductive type resistor spark plug (such as a Champion Q-type or NGK Z-type). This is because inductive resistor plugs require less voltage than a monolithic (regular) resistor plug to work. Non-inductive resistor type plugs on these motors can create an open circuit within the spark plug - creating a "dead plug".

Mallory, MSD, Crane and Accel produce a high output ignition CDI system which is very different for the marine style CDI. Some high output systems require use of resistor plugs, while others will fry the internal plug resistor turning its 5k ohms into 60k ohms. You should check with your CDI manufacturer for their recommendations on spark plugs, coils, plug wires and such.

It is strongly recommended that a resistor spark plugs be used in any motor that use an on-board computer systems to monitor or control engine performance. Use of a non-resistor plug in certain applications can actually cause the engine to suffer undesirable side effects such as an erratic idle, high-rpm misfire, engine run-on, power drop off at certain rpm levels and abnormal combustion. Resistor plugs are also recommended on any vehicle that has other on-board electronic systems such as, two-way radios, GPS systems, depth finders or whenever recommended by the manufacturer.

Spark Plug Heat Range

A spark plug's heat range has no relationship on the actual electrical energy transferred through the spark plug. The heat range of a spark plug is the range in which the plug works well thermally and is based on how a spark plug absorbs and dissipates. It's important to note that spark plug manufactures used different heat range scales and that you can not compare plugs from different manufactures without a conversion table. A lower numerical NGK heat range is hotter than a higher numerical heat range, while a lower numerical Bosch heat range is colder than a higher numerical heat range. As a general guideline, among identical spark plug types, the difference in tip temperature from one heat range to the next is approximately 70°C to 100°C.

Heat Range Table

| NGK | BOSCH | DENSO | CHAMPION |

| 2 | 10 | 9 | 18 |

| 4 | 9 | 14 | 16,14 |

| 5 | 8 | 16 | 12,11 |

| 6 | 7,6 | 20 | 10,9 |

| 7 | 5 | 22 | 8,7 |

| 8 | 4 | 24 | 6,63,61 |

| 9 | 3 | 27 | 4,59 |

| 9.5 | 29 | 57 | |

| 10 | 2 | 31 | 55 |

| 10.5 | 32 | 53 | |

| 11 | 34 | ||

| 11.5 | 35 |

A spark plug's heat range is determined by several factors:

The surface area of the ceramic insulator nose

Relative position of the insulator tip to the end of the shell (long vs short nose)

The overall thermal conductivity (ability to absorb and transfer combustion heat) of the insulator, center electrode, etc.

The structure and material composition of the insulator

The material composition of the center electrode (copper vs platinum alloy, etc)

The major structural difference affecting the heat rating is the length of the insulator nose. A "Hot" spark plug has a longer insulator nose. This longer nose increase the distance between the firing tip of the insulator nose and the base of the insulator nose where it comes in contact with the spark plug's metal shell. This longer nose increase the surface area of the ceramic to hot ignited gases as well as increases the distance heat must travel to the cylinder head. This causes a longer insulator nose to heat up faster and stay hotter than a comparable shorter insulator nose.

Selecting a proper spark plug heat range is vital for proper spark plug thermal performance. If the heat range is not optimal for you engine and driving conditions, you and experience significant problems. The optimal firing end temperature is approximately between 500°C (932°F) and 800°C (1472°F). If your spark plugs are operating under 450°C, you can expect plug fouling. If your spark plugs are operating above 800°C, you can expect plug overheating problems.

Carbon Fouling

Carbon fouling occurs when the spark plug firing end does not reach the self-cleaning temperature of approximately 450°C (842°F). Carbon deposits will begin to burn off from the insulator nose when the self-cleaning temperature is reached. When the heat range is too cold for the engine speed, the firing end temperature will stay below 450°C and carbon deposits will accumulate on the insulator nose. This is called carbon fouling. When enough carbon accumulates, the spark will travel the path of least resistance over the insulator nose to the metal shell instead of jumping across the gap. This usually results in a misfire and further fouling.

If the selected spark plug heat range is too cold, the spark plug may begin to foul when the engine speed is low or when operating in cold conditions with rich air-fuel mixtures. In some cases, the insulator nose can usually be cleaned by operating the engine at higher speeds in order to reach the self-cleaning temperature. If the spark plug has completely fouled, and the engine will not operate correctly, the spark plug may need to be cleaned / replaced and the fouling cause identified.

Causes of Carbon Fouling:

Continuous low speed driving and/or short trips

Spark plug heat range too cold

Air-fuel mixture too rich

Reduced compression and oil usage due to worn piston rings and/or cylinder walls

Over-retarded ignition timing

Ignition system deterioration

Plug Overheating

The most serious result of selecting an inappropriate heat range for your engine and/or driving conditions is selecting a spark plug that is too hot and causes overheating. Overheating will cause the electrodes to wear quickly and can lead to pre-ignition. Pre-ignition occurs when the air-fuel mixture is ignited by a hot object/area in the combustion chamber before the timed spark event occurs. When the spark plug firing end (tip) temperature exceeds 800°C, pre-ignition originating from the overheated insulator ceramic can occur. Pre-ignition will dramatically raise the cylinder temperature and pressure and can cause serious and expensive engine damage. When inspecting a spark plug that has experienced overheating or pre-ignition, blistering on the ceramic insulator and/or melted electrodes can sometimes be found.

Causes of Overheating:

Spark plug heat range too hot

Insufficient tightening torque and/or no gasket

Over-advanced ignition timing

Fuel octane rating too low (knock is present)

Excessively lean air-fuel mixture

Excessive combustion chamber deposits

Continuous driving under excessively heavy load

Insufficient engine cooling or lubrication

Reducing combustion chamber volume (i.e.: domed pistons, smaller chamber heads, milling heads, etc.)

Other engine modifications (increased compression ratios, large camshafts, turbos, nitrous oxide, etc.)

Some factors to consider in selecting the proper heat range spark plug

There are many external influences that can affect the operating temperature of a spark plug. The following is a brief list to consider in avoiding reduced performance and/or expensive engine damage.

Engine Speed and Load

If the engine is to be operated at high RPM, under a heavy load, or at high temperatures for long periods a colder heat range may be needed.

Conversely, if the engine is to be operated at low speeds or at low temperatures for long periods, a hotter heat range might be needed to prevent fouling.

Air-Fuel Mixture

Excessively rich air-fuel mixtures can cause the plug tip temperatures to decrease and carbon deposits to accumulate, possibly causing fouling and misfires.

Excessively lean air-fuel mixtures can cause the cylinder and plug temperatures to increase, possibly resulting in knock and/or pre-ignition. This may cause damage to the spark plug and/or seriously damage the engine.

If an air-fuel ratio meter or gas analyzer is not available, it will be necessary to visually inspect the spark plugs frequently during the tuning process to determine the proper air-fuel mixture.

Performance engines and driving require colder spark plugs. Mild engines and driving require hotter plugs.

Fuel Type / Quality

Low quality and/or low octane fuel can cause knock which will elevate cylinder temperatures. The increased cylinder temperature will cause the temperature of the combustion chamber components (spark plug, valves, piston, etc.) to rise, and will lead to pre-ignition if the knock is uncontrolled.

When using an ethanol blend fuel with high ethanol content in high performance applications, a colder heat range may be necessary. The spark timing can be advanced further because ethanol blend fuel has a higher resistance to knock (higher octane). Due to the decreased knock, there will be less audible “warning” from knock before the spark plug overheats and pre-ignites.

Some types of fuel additives in lower quality fuels can cause spark plug deposits that can lead to misfires, pre-ignition, etc.

Ignition Timing

Advancing ignition timing by 10° will cause the spark plug tip temperature to increase by approximately 70° to 100°C.

A colder heat range spark plug may be necessary if the ignition timing has been advanced to near the knock level. Higher cylinder temperatures near the knock level will bring the spark plug firing end temperature closer to the pre-ignition range.

Compression Ratio

Significantly increasing the static/dynamic compression ratio will increase cylinder pressures and the octane requirement of the engine. Knock may occur more easily. If the engine is operated near the knock level, a colder heat range spark plug may be necessary due to the resulting increased cylinder temperatures.

Forced Induction (Turbocharging, Supercharging)

A colder heat range spark plug may be necessary due to the increased cylinder temperature as boost pressure (manifold pressure) and subsequent cylinder pressure and temperature increase.

Ambient Air Temperature / Humidity

As the air temperature or humidity decreases, the air density increases, requiring a richer air-fuel mixture. If the air-fuel mixture is not properly richened, and the mixture is too lean, higher cylinder pressures / temperatures, knocking, and the subsequent increase in the spark plug tip temperatures can result.

As the air temperature or humidity increases, the air density decreases, requiring a leaner air-fuel mixture. If the air-fuel mixture is too rich, decreased performance and/or carbon fouling can result.

Barometric Pressure / Altitude

Air (atmospheric) pressure and cylinder pressure decrease as altitude increases. As a result, spark plug tip temperature will also decrease.

Fouling can occur more easily if the air-fuel mixture is not adjusted to compensate for the altitude. Higher altitude = less air = less fuel.

Tech Support - Spark Plugs Overview

Types of Abnormal Combustion

Pre-ignition

Pre-ignition occurs when the air-fuel mixture is ignited by a hot object / area in the combustion chamber before the timed spark event occurs.

When the spark plug firing end (tip) temperature exceeds 800°C, pre-ignition originating from the overheated insulator ceramic can occur.

Is most often caused by the wrong (too hot) heat range spark plug, and/or over-advanced ignition timing. An improperly installed (insufficient torque) spark plug can also result in pre-ignition due to inadequate heat transfer.

Pre-ignition will dramatically raise the cylinder temperature and pressure and can melt and hole pistons, burn valves, etc.

Knock

Occurs when part of the air-fuel mixture in the combustion chamber away from the spark plug is spontaneously ignited by the pressure from a flame front originating from the spark plug. The two colliding flame fronts contribute to the “knocking” sound.

Knock occurs more frequently when using low octane fuel. Low octane fuel has a low resistance to knock (low resistance to ignition)

Knock is related to ignition timing. (Knock is sometimes referred to as “Spark-knock”.) Retarding the ignition timing will reduce knock.

Heavy knock often leads to pre-ignition.

Heavy knock can cause breakage and/or erosion of combustion chamber components.

Knock is sometimes referred to as “ping” or “detonation”.

Misfires

A misfire occurs when the spark travels the path of least resistance instead of jumping across the gap.

Misfires can be caused by the following:

Carbon fouling

Worn or deteriorated ignition system components

Too large of gap size

Spark timing excessively advanced or retarded

Damaged spark plugs (cracked insulator, melted electrodes, etc)

Mismatched ignition system components (plug resistance / wire resistance, ignition coils / igniter modules, etc.)

Insufficient coil primary and/or secondary voltage – voltage required to jump the spark plug gap higher than coil output

Spark Plug Assessment

You can learn a lot about your engine by looking at your spark plugs.

The following information was taken from an NGK Spark Plug pamphlet from the late 1970's.

The appearance of the firing-end of a spark plug shows how well an engine has been operating, the suitability of the plug heat rating, and whether or not the carburetor and ignition timing are properly adjusted.

The information below is intended to assist you in correctly choosing your spark plugs and deter-mining operating condition of your engine. Even plugs presenting a good appearance, as those shown in Figures 6 - 24, can quite often be covered with lead deposits, which cause misfiring.

Figures 1 - 2 show wet plugs and are normally attributed to one of the following causes:

Excessive chocking.

Trouble within the ignition system.

Oil pumping past warn piston rings and valve guides.

Figures 3, 4, and 5 show the sooty plugs, which are usually the result of:

A plug with too high a heat rating being used and the firing-end not reach it's self cleaning temperature of 750 - 840 deg. F. also may be due to too light prop loading conditions.

Use of air-fuel mixtures richer than about 8:1 - 10:1

Trouble in the ignition system.

Excessive cooling usually caused be an improperly functioning cooling system.

The plugs illustrated in Figures 25, 26, and 27 show varying degrees of melting of the electrode and may be the result of:

Oil pumping past worn piston rings And valve guides.

Plug heat rating too low, permitting the plug to exceed the optimum operating temperature range of 1560 - 1830 deg. F. usually due to operating with an excessively high loaded prop.

Air-fuel mixture too lean.

Over advanced ignition timing.

Abnormal combustion such as knocking.

Excessively engine operating temperatures.

Figures 28 and 29 show plugs that have been over heating due to intense knocking and pre-ignition.

|

|

|

|

| 1 Oil Fouled

|

2 Oil Fouled

|

3 Carbon Fouled

|

4 Too Cold

|

|

|

|

|

| 5 Too Cold

|

6 Cold or Rich But OK

|

7 Cold or Rich But OK

|

8 Cold or Rich But OK

|

|

|

|

|

| 9 Good

|

10 Good

|

11 Good

|

12 Good

|

|

|

|

|

| 13 Real Good

|

14 The Best

|

15 Best

|

16 Best

|

|

|

|

|

| 17 Best

|

18 Good

|

19 Good

|

20 Good

|

|

|

|

|

| 21 Kinda Hot But OK

|

22 Hot or Lean But OK (?)

|

23 Hot or Lean But OK (?)

|

24 Hot or Lean But OK (?)

|

|

|

|

|

| 25 Too Hot or Lean Pre-Ignition Range

|

26 Too Hot or Lean Pre-Ignition Range

|

27 Too Hot or Lean Pre-Ignition Range

|

28 Too Hot or Lean Pre-Ignition Range

|

|

|||

| 29 Too Hot or Lean Pre-Ignition Range |

|

Normal Grayish-tan to white in color indicates the plug is operating at the proper heat range as well as correct jetting and the cylinder is running healthy. |

Worn Electrode wear, misfire during acceleration and hard starting especially in damp or cold conditions.

Simply put as in its description, it's worn out ... it looks ok color wise, so replace it with same plug or at least compatible heat range. Change your plugs more often! |

Mechanical Damage This is caused by foreign objects in the combustion chamber or an improper plug reach where it contacts the piston.

To solve this, make sure you have the correct length tip spark plug as well as removing any foreign materials in the combustion chamber. |

|

Detonation In cases of severe detonation, insulators may become cracked or chipped. Improper spark plug gap settings will also cause the insulator tip to crack or chip.

Make sure that you are using the correct octane fuel first (Premium for DOHC / performance computers) and then verify correct ignition timing. Next check for an inoperative EGR system as well as proper function of the Knock Sensor. Also, you will want to make sure you are using the correct heat range plug, properly gapped. |

Excessive Heat Chalky appearance, white insulator, rapid electrode wear as well as an absence of deposits. The actual shell may also be discolored.

To cure this you must first verify that the plug is the correct heat range, the ignition timing settings are correct, the air/fuel mixture is not too lean, there are no vacuum leaks or sticking valves and that the EGR valve is functioning properly. |

Ash Deposits These are light-brownish deposits that are encrusted to the ground and/or center electrode. This situation is caused by oil and/or fuel additives. This condition can cause misfires.

The cure for this is to verify worn valve guides or valve seals, not using fuel additives, or you might even try changing fuel brands. |

|

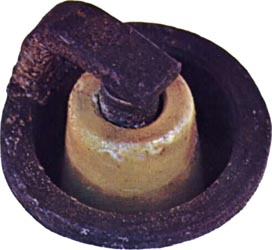

Oil Fouled (Wet) Oily coating caused by poor oil control. Oil is leaking past worn valve guides, piston rings, or on some race engines a possible intake gasket leak and then entering the combustion chamber.

Check for worn valve guides, intake gasket sealing alignment, as well as worn cylinder walls and piston rings. A leak down test is a good place to start for what is causing this. |

Initial Pre-Ignition This will usually look as a melted center electrode and/or ground electrode.

Check for incorrect heat range plug, over-advanced timing, lean fuel mixtures, inoperative EGR valve or Knock Sensor (if equipped) and also look for hot spots or deposit accumulation inside the combustion chamber. |

Sustained Pre-Ignition This will be pretty obvious ... melted and/or missing center and/or ground electrodes as well as a destroyed insulator.

Check for incorrect heat range plug, over-advanced timing, lean fuel mixtures, inoperative EGR valve or Knock Sensor and also look for hot spots or deposit accumulation inside the combustion chamber.) After you see this, you'd better look for possible internal engine damage as well. (pistons, cylinder walls, valves, rings, etc.) |

|

Carbon Fouled Soft, black, sooty, dry-looking carbon. This indicates a rich mixture, weak ignition or wrong heat range plug (too cold.)

You will first need to verify plug heat range. Check for clogged injectors. Clean the air filter. Lastly on all engines, check for vacuum leaks and weak spark or low voltage output. |

Splashed Deposits

These look as if they are small islands of contaminants on the insulator. This is usually a dirty carburetor bores or air intake as well as the possibility of a dirty or faulty injector.

You must use aggressive carb and choke cleaner or other solvent cleaner (a pressurized fuel injection service on fuel injected vehicles or injector removal and cleaning) before installing new spark plugs. |

http://www.bikerenews.com/Stories_Archives/Sparkplugs/Spark_Plugs.htm

Please feel free to link to this site so that others can find it. It's easy to link to this site, just copy one of the texts below onto your web page:

Copyright © 2000-2010